Meeting the trade requirements of a manufacturing unit can be challenging, as the right tool is troublesome to find. Cutting, sanding, knurling, drilling, cutting & more can be tough to accomplish tasks in the modern era where you need the proper tool that satisfies the business standards. The Lathe Machine is an apparatus that fulfils these business objectives with comfort. Making amazing products is easy with the tool. However, few operations are a part of the machine’s working that only a few people know. Let’s figure out this:

Before getting into the details regarding the process of the machine, let’s know what it is:

What Is A Lathe Machine?

This type of machine is useful when you require work like cutting, turning, sanding, knurling, drilling, and more. The tool rotates a material (that is, to be turned into the desired shape) to a fixed axis for operating. The tool is highly efficient for the cutting of woods, creating identical shape objects, pattern making, cutting metal, metal spinning, and more. Depending upon your desired work, you can use the machine and create stupendous products for your firm.

What Are The Top Lathe Machine Operations?

There are numerous operations you can perform using the lathe machine suppliers in India products.

Operation One – Turning

It’s a machinery operation where you press the workpiece in the lathe chuck & rotate it. Once the process is done, you shape the workpiece by using a single-point cutting tool. This tool is attached to the tool post of your lathe machine. It’s known as the simplest lathe machine operation you can do at present. We can easily do the operation of plastics, metals, and wood. The method helps remove the material from inside or outside of the workpiece.

Operation Two – Facing

It’s again important that it is used for smoothing and flattening of the closure surface. It’s a common operation performed by almost every lathe machine user before the other operations. The operation can be done by pressing your workpiece on the lathe chuck & moving the cutting tool near the end surface of the workpiece. The best part about this operation is that you can set the depth of cutting as per your requirement. Now, after doing this, start the motor & feed the cutting tool internally.

Operation Three – Threading Lathe Machine

It’s again a process that is very useful for creating the screw thread on the workpiece. The product of lathe machine manufacturers in India will help you perform continuous cuts using a threading tool identical to thread shape. This operation is done to cut various threads like metric, imperial, acme, and more. Be sure you train your machine operators before doing this operation, as it needs a highly skilled technician.

Operation Three – Grooving

There are two types of operations you can perform on the lathe machine: OD grooves and ID grooves. We can use different grooving tools for each operation. A grooving tool is best for cutting in a single direction only.

Operation Four – Knurling

This type of operation where you create the pattern of straight, cross line, or angled over the material surface using the knurling tool. The process will allow your hands/fingers to have a better grip over knurled objects other than the existing smooth metal surface.

Operation Five – Parting

It’s again an important procedure where you use the tool of Lathe machine suppliers to cut a workpiece. We know the process as parting, where you cut a workpiece into two pieces using a thin & long parting tool comparable to a blade. A parting process is thus helpful in cutting any piece size from the raw bar to make it a workpiece.

Operation Six – Boring

It’s the other important operation where you produce conical or cylindrical surfaces by expanding an existing opening in the workpiece. This process is highly effective for enlarging the holes or for cutting the tapered hole. We know the surface formed by this operation as the bore.

Top Advantages You Can Have With Lathe Machine

- The accuracy of the lathe machine is extremely high. Its variant CNC lathe is better than the normal lathe.

- The production units you can get with this machine are very high.

- The third advantage you can have with the lathe is, it only needs very few operators to run the manual lathe machine.

- The machinery is highly fast and performs every operation accurately.

- The other advantage with the machine is, the lead time will be highly less.

Try Finding The Right Manufacturer For Buying The Machinery!

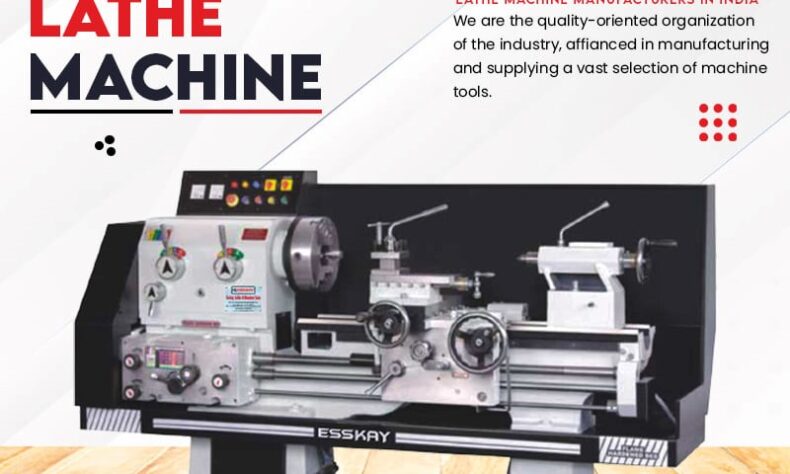

Esskay Lathe And Machine Tools one of the reliable lathe machine exporters in India. There are many exporters out there who deliver quality lathes to consumers all around India. Try finding the one that is from a genuine manufacturer who has a name in the market. Lathe machines can help you make various products like a baseball bat, pen, metal bullets, wedding rings, ice cream scoop, wooden spoon/bangles, and more. Get it right now to grow your manufacturing and earn an attractive income after selling your wood or metal items.

You can make your business a recognized name among your people. All you have to do is find the lathe that suits your needs and buy it from their site at a reasonable price. Read our other blogs for getting the most useful information on the web about machines.