The importance of Sand Blasting Machine is great in the present world as cleaning has become important in the present era. The process is helpful for the industries where the industrialists are conscious of the environment. A right blasting machine will remove the dust particles in an easy way. Let’s know everything about it and find out the equipment used in it:

What is a Sand Blasting Machine?

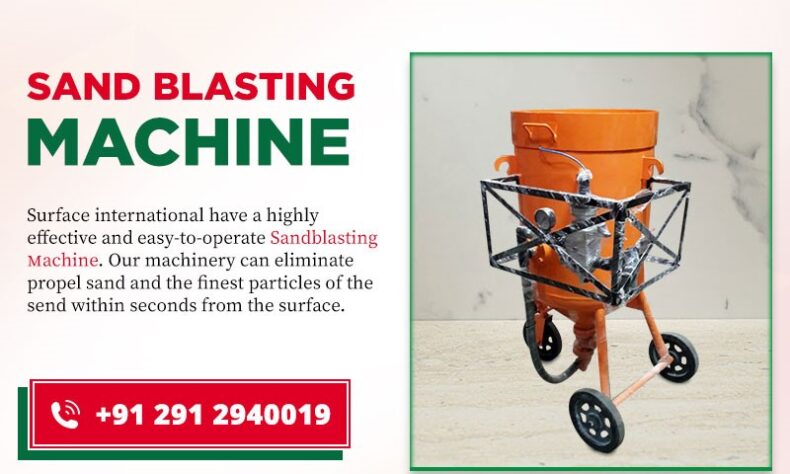

Nowadays, a wide range of associations use sandblasting procedures for cleaning surfaces in numerous industries. Essentially, it offers an extraordinary approach to cleaning harms caused by water, oil, fire, form, and numerous different reasons. Generally, this is the best cleaning technique that helps in reestablishing a property back to its unique design. It can clean the damaged part of the surface and make it smooth.

The sand blasting process can be done quickly. Subsequently, this cleaning procedure will help you in saving a great deal of time and cash too. Henceforth, in the event that you are using the machine of famous sand blasting machine suppliers in India, only then all the residue particles can be taken out appropriately and rapidly.

Working Of The Sand Blasting Machine

Assuming you are a proprietor of an organisation or your work profile is like sand impacting work, you should be familiar with how sand impact machines work. In this article, we will incorporate practically every one of the subtleties connected with the sand blasting machine tool and its work techniques. Be that as it may, before we make sense of it let us additionally educate you on something else.

Operation Of The Sand Blasting Machine

Sand blasting is a strategy for moving rough involving packed gas or compressed fluid as hazardous. There are different conventional terms for this use; ordinarily it is connected with the grating media.

Sand Blasting is a surface treatment strategy utilising high-speed steel grating. Sand impacting is the strategy through which acquiring prevalent cleaning and surface gear for auxiliary completing operations is conceivable. The rough is gathered in the power compartment then fixed.

This is the most common way of leaving fine sand at high strain with the assistance of packed air that is gotten through the spout at an exceptionally high speed.

The Operation Sand Blasting Requires a Diversity of Equipment

Portable Blast:

The compressed vessel is for the most part utilised in applications that contain the grating and metre it into the packed air stream. Wet impacting is performed by infusing the rough into a compressed water stream or making a slurry of grating and water that is compressed or remembered for a packed air stream.

Automated Blasting:

It is a robotized impact that gives surface hardware and covering applications to lessen the impacts nature can have on manufactured steel, with least or no effect on the climate.

Impact Cabinet:

A commonplace impact bureau has four components; the control, the sand impacting framework, the grating reusing framework, and the residue assortment. The administrator shoots the parts from the finish of the bureau by putting his arms in gloves associated with glove openings on the bureau, a view window for the survey of the component, and, ordinarily, turning the impact on and off utilising a foot pedal or lever.

Top Areas Where You Can Use the Sand Blasting Machine

The sand impacting machine is utilised in different regions, for example,

- Railroad mentors

- Painstaking work and wood

- Steel pipes

- Stones, Marbles, Granite

- Transformers and Tanks

- Military

- Shipyards

- Spans

- Turbines

Top Advantages You Can Have with the Sand Blasting Machine

Grating Activity on a Superficial Level

The rough materials which are being utilised in the process have a forceful activity on the surfaces.

Fit for unpleasant surfaces

The strong activity can eliminate pollutants from extreme surfaces like cement.

Fast Removal of pollutants

Removal of the stores of the impurities rapidly from the various surfaces.

Less hardware is involved

Abrasive impacting doesn’t include complex apparatus.

Find the Right Machine for Your Business

Finding the proper blasting machine for trade is easy nowadays, as many suppliers are available online. Choosing one out of the many sand blasting machine manufacturers in India should be your choice, as they may have the perfect best products. The right equipment will run for years, whereas the wrong one may work for a year or two. If you want stability in your industry and wish to grow easily in the future, buying the right sand blasting apparatus should be your priority.

Maintaining the surface wash after the operation is done in the factory is mandatory. Make sure that the company you are selecting has created trust among its audience and is noted for its works. Surface International is a reliable brand is all you seek to maintain surface cleaning in your industry. Find the firm today!